For many years, tube and pipe mills have utilized “group” drive gear trains. This was the most economical method for providing power to drive the roll shafts of your tube or pipe mill and utilized relatively low-cost worm gear units that are grouped together to drive specific sections of a tube or pipe mill (i.e. breakdown, fin-pass, pull-out, sizing, reshaping, etc.). During this time, the electronic portion of the equation found the proper algorithms to support the group drives to ensure proper trim level relationships with the overall drivetrain itself.

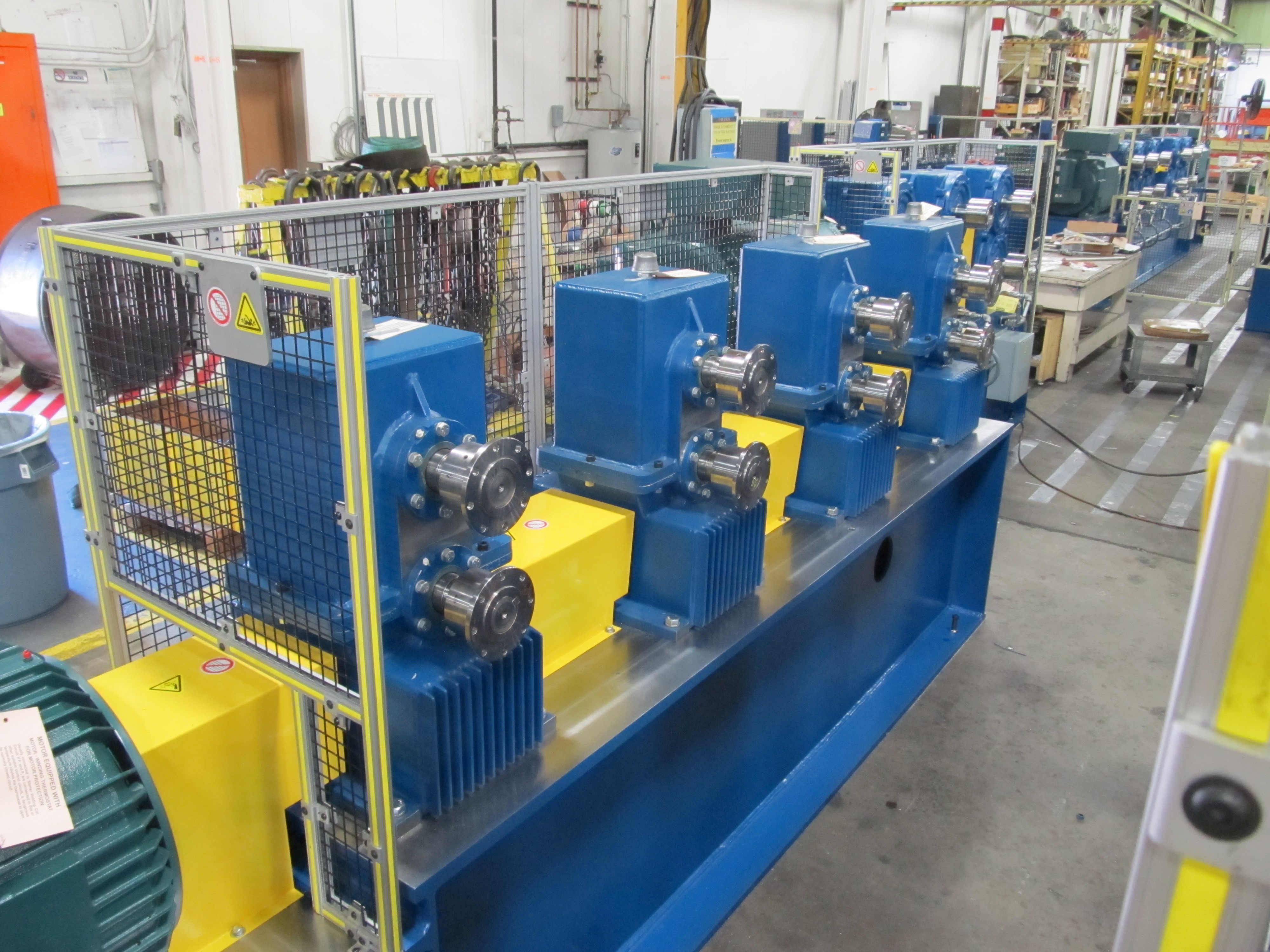

As years went on, newer technologies were being implemented with large pipe mills and drivetrain system. Grouped drivetrains were morphing into individual motor per stand type systems. No longer confined by the group drive shell (driven by worm type pinchroll reducers, coupled together with other reducers and driven by one (1) AC motor); now each roll stand had the ability to be trimmed separately. Why did the large pipe mills adopt this technology? Essentially cost vs. the improvement of the system:

As years went on, newer technologies were being implemented with large pipe mills and drivetrain system. Grouped drivetrains were morphing into individual motor per stand type systems. No longer confined by the group drive shell (driven by worm type pinchroll reducers, coupled together with other reducers and driven by one (1) AC motor); now each roll stand had the ability to be trimmed separately. Why did the large pipe mills adopt this technology? Essentially cost vs. the improvement of the system:

- The electronic portions (which were previously too expensive to consider) had dramatically decreased in price.

- The mechanical gearing portions (worm screw type system) had increased in price

- Large horsepower motors (required to drive the worm screw groups) were no longer being made and if they were, were very expensive.

- Worm screw drivetrains have an overall lower mechanical efficiency due to the worm screw transmission when compared to inline helical type systems. This translates to less power used (or wasted) and when you consider over a 1000 horsepower to drive large pipe mills, this can amount to lots of saved power.

Overall, the large pipe mills were justified by heading into this level of drivetrain sophistication. Several years later, this type of drive/gear train system would find itself being used in smaller mills where you had specific characteristics that would support the added costs of this type of system (such as higher yield strength materials, faster processing speeds, heavier wall thicknesses per a specific OD, etc.). Combinations of these variables added enough complexity to the system that in some cases, this drive/gear train system is required but still lacked some finesse.

Overall, the large pipe mills were justified by heading into this level of drivetrain sophistication. Several years later, this type of drive/gear train system would find itself being used in smaller mills where you had specific characteristics that would support the added costs of this type of system (such as higher yield strength materials, faster processing speeds, heavier wall thicknesses per a specific OD, etc.). Combinations of these variables added enough complexity to the system that in some cases, this drive/gear train system is required but still lacked some finesse.