Whether you're a roll forming industry veteran looking to refresh your knowledge or a newcomer eager to delve into the fascinating world of metal forming, understanding the fundamental terminology is essential to success. Key roll forming and die tooling terms are the building blocks of this highly specialized field, and grasping these terms empowers engineers, fabricators, and enthusiasts to communicate effectively, troubleshoot issues, and, ultimately, achieve precision and efficiency.

In this blog post, we'll define the essential terminology that underpins the art and science of roll forming and dies.

Roll Forming Design Terminology

Step Off Alignment: When roll tooling is designed in such a way that the spacers of different lengths are used to save on the amount of tool steel used to manufacture the roll tooling.

Straight Roll Alignment: When roll tooling is designed with the first pass in the same width as the last pass and all the inboard spacers are the same length.

Finish Pass: The final pass or passes of the set of roll tooling that is made to the final product dimensions.

Over Bend Pass: The pass or passes that are designed into the set of roll tooling that takes the product and forms the material past the product design intent so the spring back and the material variations can be controlled.

Roll Stops or Traps: The portion of the roll tooling that holds the flat stock in each individual pass and keeps the material from wandering out of the pass.

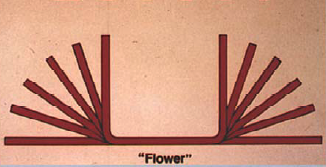

Flower Pattern: The concept the roll designer will come up with to determine the number of passes required to form the product and to determine how much forming will be performed in each pass.

Roll Splits: This term is used to identify where two rolls will be put together.

Form Angle: The angle method that is used during the roll tooling design process to determine the number of forming passes needed and the point where the roll designer decides on the amount of forming for each pass.

Lift Angle: The amount of bending that will be done in each pass of roll tooling.

Die and Tooling Terms Defined

Stationary Die: A die that is bolted to the press and does not move during forming. It is usually used as a pre-notch die but in some cases used as a mid-pierce, post-pierce, or cut-off die with a start-stop roll forming. If it is used with conventional roll form line, it must have a loop system to keep a slack loop if material between the roll former and the press.

Flying Die: A die that moves with the material and punches as it goes through the roll form line. It can be used as a pre-notch, mid-pierce, post-pierce, and a cut-off die. It is typically used with a die accelerator or pick up system to position the holes in the correct location.

Die Stops: Usually a block of steel mounted inside the die to help during setup of the die to ensure the shut height is set properly.

Die Tracks: Slides mounted on the top and bottom of the die that interlock with track on the press to enable a flying die to move with the material.

Punches and Buttons: The actual part of the die that will pierce the features into the material. The punch will be forced down onto the material and be aligned to the button that supports the material as the punch passes through.

Guide Pins and Bushings: The guiding mechanism for the die set. To ensure that the punches enter the button properly, the guide pins and bushing align the top die shoe to the bottom die shoe.

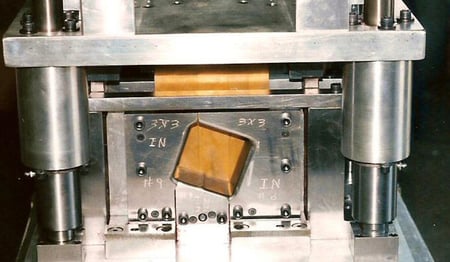

Shut Height: Describes the die completely closed and all the punches and buttons entered properly.

Open Height: The die at its maximum opening.

Die Clearance: The clearance required between the punch and button. It will be different depending on the material being punched and can be anywhere from 5% to 25% of the material thickness.

Die Set: The complete top and bottom portion of the die where the guide pins, bushings, punches, and buttons are mounted.

Die Shoe: Describes the top or bottom portion of the die set.

Gag Die: A die that has a moveable punch backer plate that is moved by an air cylinder to allow the punch to pierce to feature or not as required for the part.

Stock Guides: Special keepers built into the die, usually cam followers, to control the material location relative to the punches.

Stripper: The portion of the die that pulls the material off of the punches after the punches have gone through the material. These can be stationary or moveable.

Pick Up: A mechanical locator to position the die relative to previously punches features. These can be mechanical or air actuated to insert or release the finger that locates it.

Crop or Slugless Cut-Off Dies: A style of die that is built with a scissor or shearing action and cuts the part off without generating a slug.

Blade Style Cut-Off and Pierce Die: A die that generates a slug when cutting off the part.