There are companies that design and engineer production lines from start to finish for steel framing production systems. Due to heavy competition domestically and globally, these organizations focus on providing customized programs to meet a customer’s specific industry goals. Many of the more successful and innovative operations provide equipment programs that include quality, flexibility and productivity with minimal manual adjustment required.

There are companies that design and engineer production lines from start to finish for steel framing production systems. Due to heavy competition domestically and globally, these organizations focus on providing customized programs to meet a customer’s specific industry goals. Many of the more successful and innovative operations provide equipment programs that include quality, flexibility and productivity with minimal manual adjustment required.

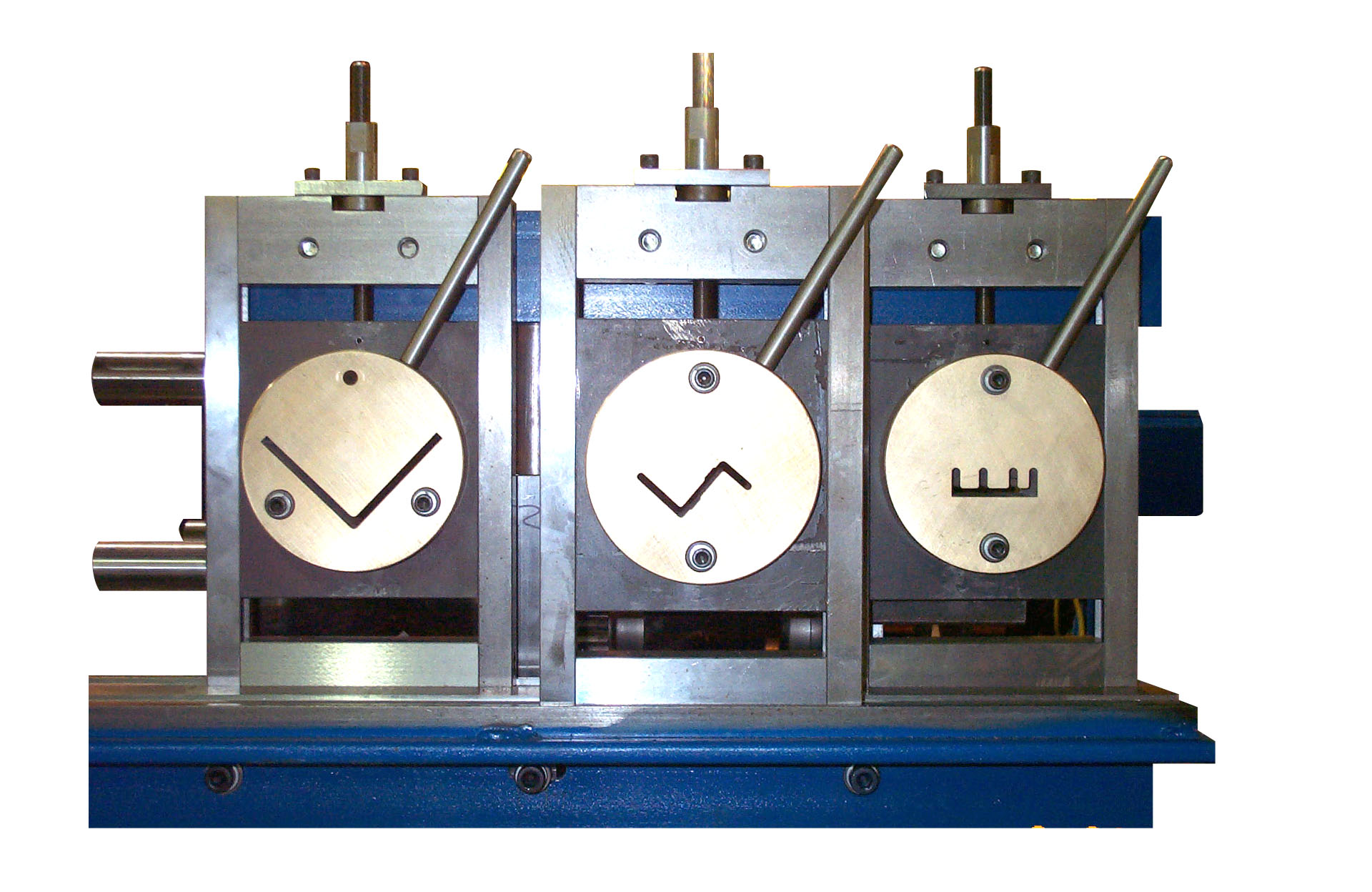

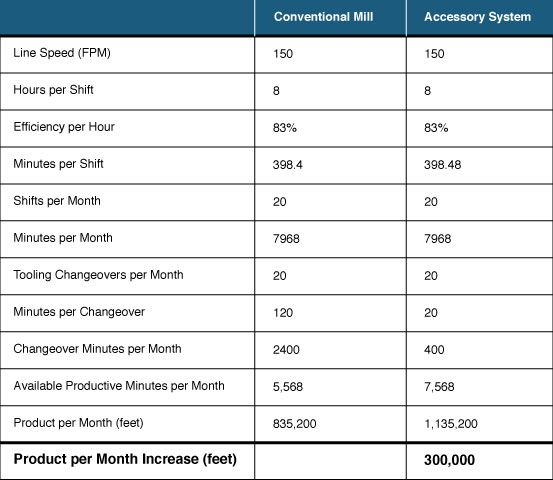

This type of equipment provides the capability to produce a variety of steel framing accessories on a single system with minimum changeover time. As highlighted in the Conventional Mill versus Accessory System chart below, the single changeover advantage dramatically raises the bar on production to bold and aggressive new levels.

Robust and advanced accessory systems can fabricate multiple profiles (up to eight profiles per system without manual changeover) and easily meet short lead times and manage heavy customer demand. Systems that offer the addition of a hand crank and mechanical readout accessory can significantly reduce monthly changeover time from 40 hours to as little as 6 ½ hours. This significant savings can equate to nearly 3 months of available production time, annually – valuable time that can be reallocated for new production projects. Accessory roll forming systems that include fast changeover also increase the amount of profile production.

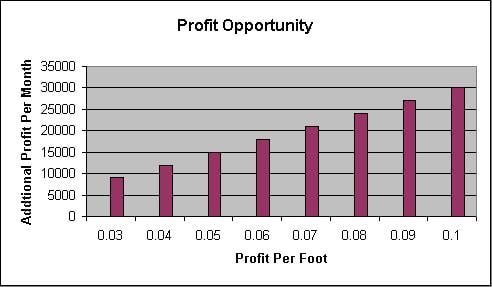

Depending on the application, an increase of as much as 300,000 feet per month can be realized. This is a measurable improvement of almost 40% over a conventional mill processing machine. Additional Accessory modules also assist in the expansion of multi-profile offerings and can provide equipment efficiencies that often result in major sales growth along with significant increase of market share. In addition, high speed productivity and a high speed operation ultimately result in a high performance system that delivers a best-in-class product. The benefits of an accessory roll forming system not only create huge production efficiencies and sales opportunities, but many times result in another significantly positive impact - that of a strong net promoter score, which can help foster a positive reputation in the market, strengthening an organization’s customer base.

Steel Framing Accessory Systems Increases Profits

To illustrate the increased profit opportunity of an advanced multiple profile accessory system versus a conventional mill system, the following analysis chart shows a typical monthly production (profit) opportunity. This comparison is based on system changeover time from one product to another.

Due to the pre-cut method of processing, the resulting leftover scrap is negligible when switching between accessory profiles. With consideration to change-over time and scrap from setup, this accessory system can easily produce small runs, significantly reducing the need for holding and maintaining finished inventory. Thus significantly reducing cost of goods.

Whether producing furring channels, resilient channels, corner bead or other roll formed accessory profiles, when selecting the right equipment for line expansion to facilitate new business growth opportunities, consider accessory systems that can help increase productivity, reduce labor costs and provide high throughput. With current innovations, advanced equipment is available which provides manufacturers of light gauge steel framing and accessories the latest technology for more productive metal forming solutions.