THE MACHINES

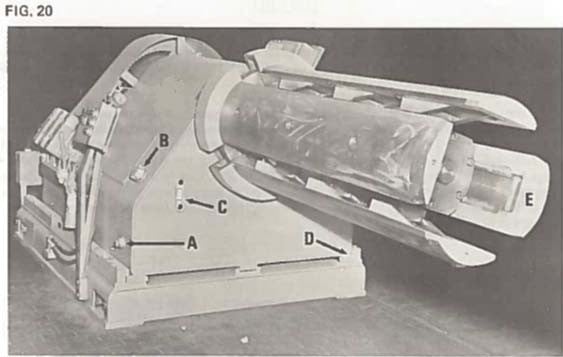

Although design details vary, slitting installations fall into either of two very distinct design styles. A good many lines for light gauge, small coils of narrow width (Fig. 17) have the slitter and recoiler assembled on a common base. Some even have the uncoiler and scrap winder on that same base. (Fig. 18)

These are the “package” type lines. Several manufacturers make this style as pull-through, or drive machines, or as a combination of both. In general, the application of this type machine is restricted to maximums of 10,000 lb. coils, .095” gage, and, 36” wide.

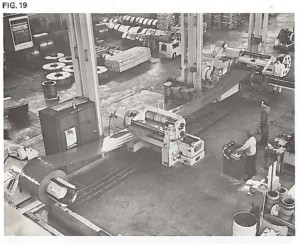

In contrast, the “customized” or multi-unit lines (Fig. 19) find extensive application throughout the complete range of coil weights, metal widths, thicknesses, cutting capacities, and speeds. These “customized” lines are likely to vary from 12” to 84” wide, for gauges as light at .005” to as heavy as ½”, for coils from 100 to 1,000 lbs. per inch of width or more, with slitter arbors from 2” to 12”, and for speeds up to possibly 2500 FRM. Remembering the limits of this discussion, however, let us examine only the components of a typical multi-unit sheet coil installation.

UNCOILER

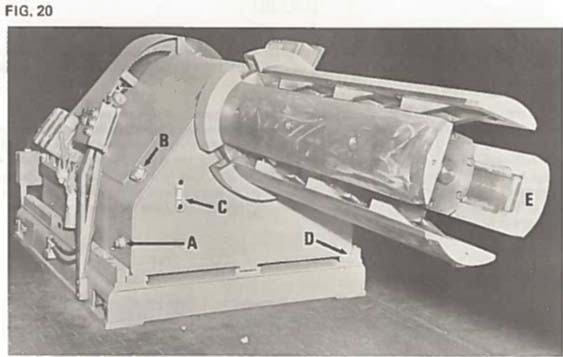

The expanding mandrel type of uncoiler (Fig. 20) is most common and employs a hydraulically expansible drum to grip the coil at its core. The drum is carried on cantilevered shaft rotating in anti-friction bearings and supported in a welded or cast frame. A feeding drive, a braking system, and a lateral adjustment complete the requirements.

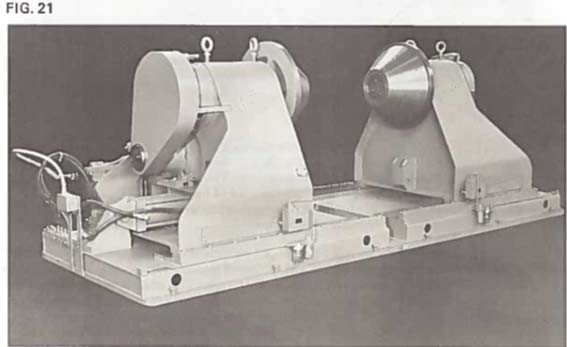

For applications where the coil weight is too great for an overhanging mandrel, a cone or stub mandrel (Fig. 21) is used.

A) Hydraulic Reservoir Drain Plug B) Hydraulic Reservoir Filler Cap and Strainer C) Hydraulic Reservoir Sight Gage D) Traversing Base E) Four Segment Wedge Drum

A) Hydraulic Reservoir Drain Plug B) Hydraulic Reservoir Filler Cap and Strainer C) Hydraulic Reservoir Sight Gage D) Traversing Base E) Four Segment Wedge Drum

SLITTERS

There are about as many slitter designs as there are manufacturers, but common to all is a pair of arbors, a drive, a base, and an entry guide system; that is where the similarity stops. We will not develop or compare the merits of each, but, a quick look at fundamentals is certainly in order.

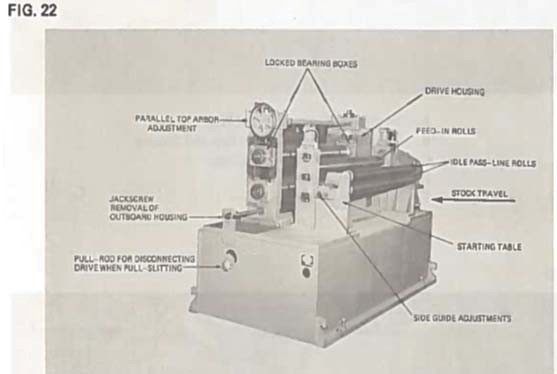

Precision is the key note. The arbors must be amply proportioned for minimum deflection at maximum load. The bearing fits and arbor tolerances must be established and maintained at an accurate level. The machine design must readily accommodate cutter set-up changes and penetration adjustments, and provide for feeding and guiding the metal. Figure 22 illustrates a design with arbor sizes up to 6” and for coil widths to 48”. Here, cutter penetration is adjusted by moving the top arbor with respect to the bottom one using a hand wheel on the operator’s side of the outboard housing. The outboard housing is removable from the arbor ends so the tooling can be stripped.

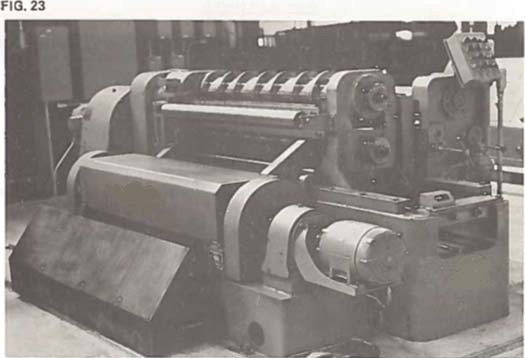

A design that is somewhat unique but nevertheless a design gaining popularity in the heavier machine category is shown in (Fig. 23). On this slitter the upper arbor is stationary and the bottom arbor adjusts vertically for penetration. The weight of the arbor and tooling assembly is supported from below by the screws instead of hanging from them. The advantages of this arrangement is that the backlash of adjusting screws is taken up in the idle condition, and requires no further adjustment when loaded.

Anything that can be done to reduce cutter set-up time should be done if maximum out-put is to be obtained. Powered penetration and outboard housing adjustments help somewhat on this score, but removable head type slitters go all the way. The arbor assembly can be lifted off a sub-base, leaving the drive and all other accessory equipment in place. A spare arbor assembly that has been tooled “off line” is then set into position and the slitter is ready to run. Usually a cutter set-up consumes from about 30 minutes to an hour, whereas, the interchange of a preset housing assembly requires on about 10 minutes. The savings are obvious.

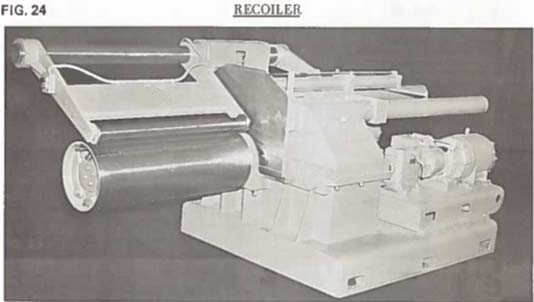

The typical recoiler (Fig. 24) includes a drum, a drive train, and a stripper. Most generally it, like the uncoiler, is a cantilevered design with the drum carried on the extended low speed shaft of a gear reducer. The high speed shaft of the reducer is coupled to the drive motor.

The drum should present an unbroken cylindrical surface when expanded. It should be collapsible so the coil can be stripped off after winding and it must provide a means to grip the strand ends at start-up. These two functions are usually performed manually because they consume very little time; but they too, in the interest of maximum output, can be powered.

RECOILER DRIVE

Since the recoiler drive in a pull-through installation governs line speed and has considerable bearing on over-all line performance, its design should certainly receive more than just casual attention. Characteristics should include smooth accelerations, smooth deceleration, speed adjustment, jogging, braking, stall tension, efficient use of power and, of course, minimum maintenance.

FANOUT & COIL SEPARATION

The slit strands are separated as they are wound on the recoiler drum by thin discs usually from 1/16” to 3/32” thick. Thus, the overall width of the rewound coil on the drum is greater than the summation of cut widths. This differential, when related to the distance between slitter and recoiler is known as “fan-out”. Obviously the drum face must be wide enough to accommodate the accumulation of separators and strands, but of more importance, the strands must be distributed equally to the right and left of center. Also, the recoiler must be positioned far enough away from the slitter so “fan-out” does not tend to develop camber.

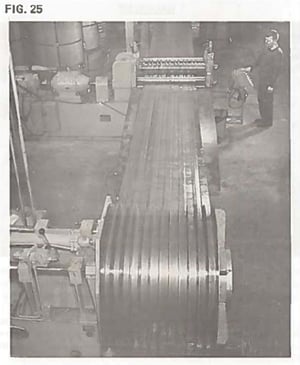

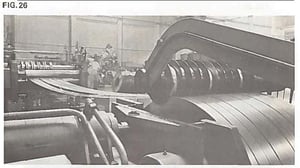

Separators may be discs slightly larger than the maximum coil diameter, (Fig. 25) or they may be small discs assembled on an overarm separating device (Fig. 26). The overarm separating unit eliminates handling large discs for each coil, as they do get heavy and bulky. The unit also functions as a hold-down to retain the strands when they tail out of the slitter.

SCRAP DISPOSAL

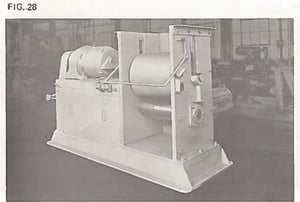

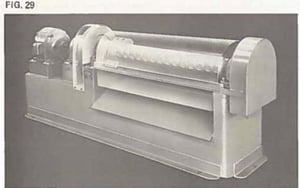

The device to be used for scrap disposal depends on several factors, such as the gauge of metal, the relative value of balled, wound, and chopped scrap on the local market, and the established in-plant handling facilities. A winder (Fig. 27) creates a relatively loose, level wound coil; a baller (Fig. 28), a solidly compacted bundle; and a chopper (Fig. 29), short pieces. The typical sheet coil line, being limited to ¼” thick material would most likely have a winder or a baller, but heavier lines demand choppers. The noise level of the chopper type may not meet the recent standards set by the Labor Department.

Model No. 1 Scrap Chopper, for mild steel stock up to .095” thick. The rotating cutter head and dual flywheel arrangement is driven by a high slip AC motor through a gear reducer.

The rotating head has four cutting edges, arranged to cut alternately on the two selvage edges.

The one shown is intended for a line in which one edge of the stock is always adjacent to the inboard housing. Thus, as indicated by the arrows, the inboard cutting edges are relatively short, and long cutting edges are provided on the outboard side to accommodate various widths of coil.

Where stock is processed on centerline, the rotating head is made with equal lengths of cutting edges on each side of center.

COIL FEEDING AIDS

Once the coil is placed on the uncoiler and the circumferential band is removed, the outer wrap must be peeled and the end transported from the uncoiler to the slitter. When stiff material is involved, the coil should also be controlled to prevent it from “clock springing” and thereby endangering personnel.

If it is necessary to slit coils that consistently average thicker than .095” and wider than 36”, it is then important to consider the mechanical coil feeding aids available. Such aids are as follows:

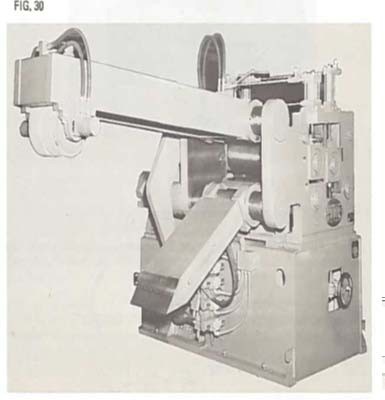

- The combination of a hold-down roll, a peeling spade, and a flattener unit, (Fig. 30) including a table from it to the slitter, and a table from the slitter to the recoiler.In this system the hold-down roll retains the outer wrap and thus prevents the coil firm “clock springing”. The holding roll is driven and, with the aid of the uncoiler threading drive, propels the leading end over the peeling spade.The spade opens the outer wrap, “breaks the strip’s back”, and serves as a threading apron to guide the coil end between the feed rolls of the flattener. They in turn drive it beneath the top bending roll, which has been lifted, and over the bottom roll at the exit side of the machine. The top bending roll is then brought down to remove the coil set, thereby making it easier to insert the end into the slitter pinch rolls when it reaches that point.

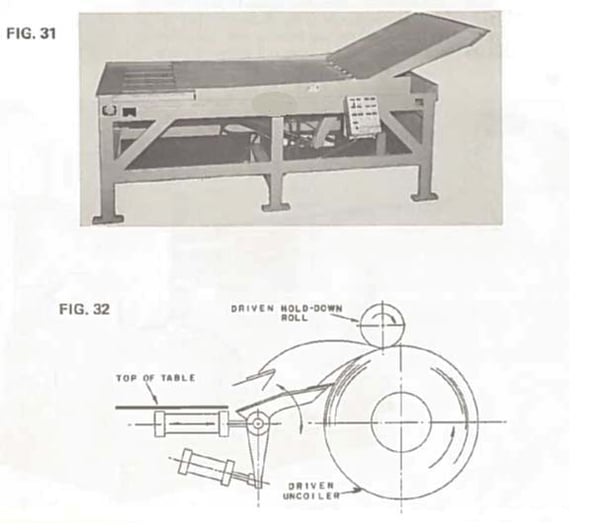

- A driven hold-down roll, cantilevered over the uncoiler, working with a combined peeler and entry threading table, (Fig. 31) and a table from slitter to recoiler represent an excellent compromise system for essentially the same purpo This unit is less expensive, roughly half the cost, but requires greater manipulation on the part of the operator, and does not remove the coil set. The peeler spade is pivoted from the end of a powered slide on the table. Both actions are used in conjunction with the hold-down roll to peel, break, and thread. Successive manipulations of the peeler (Fig. 32), while the metal is being simultaneously driven forward, reduces the normal generous coil curvature into successive smaller scallops.

Without these devise, light gauges are threaded simply by a team of men, dependent on the coil width, supporting the end and walking with it to the slitter as it is paid off by the threading drive. Heavy gauges, on the other hand, in addition to time, might very well require the use of crowbars, sledge hammers, and two to four men, plus the use of an overhead crane as a pulling force, or the recoiler as a winch, to open up the coil and thread it into the slitter.

This post is part of the series, “Rotary Slitting Principles and Applications.” Here are links to the other posts in the series:

This post is part of the series, “Rotary Slitting Principles and Applications.” Here are links to the other posts in the series: