The capability of any given machine with regard to height or depth of the section is measured mainly by the vertical distance available between spindles. This, together with the distance from the centerline of the bottom spindle to the top of the machine base and the horizontal center distance between roll stands, establishes the maximum roll diameter.

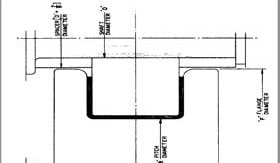

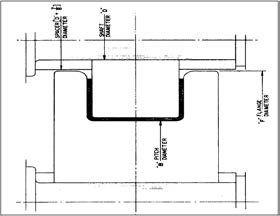

Let us look at the roll contour of the last roll stage for a simple channel as on the diagram above and note it relation to the other parts of the machine. In addition to the restrictions just mentioned, there must be clearance between the outside diameter of the bottom roll flange and the top roll spacer, as well as clearance between the edge of the section and the top roll spacer. Note also the bottom roll flange diameter includes a lead-in or bell-mouthed contour to aid in threading from one pass to another.

Roll Pitch Diameter and Gearing Ratio

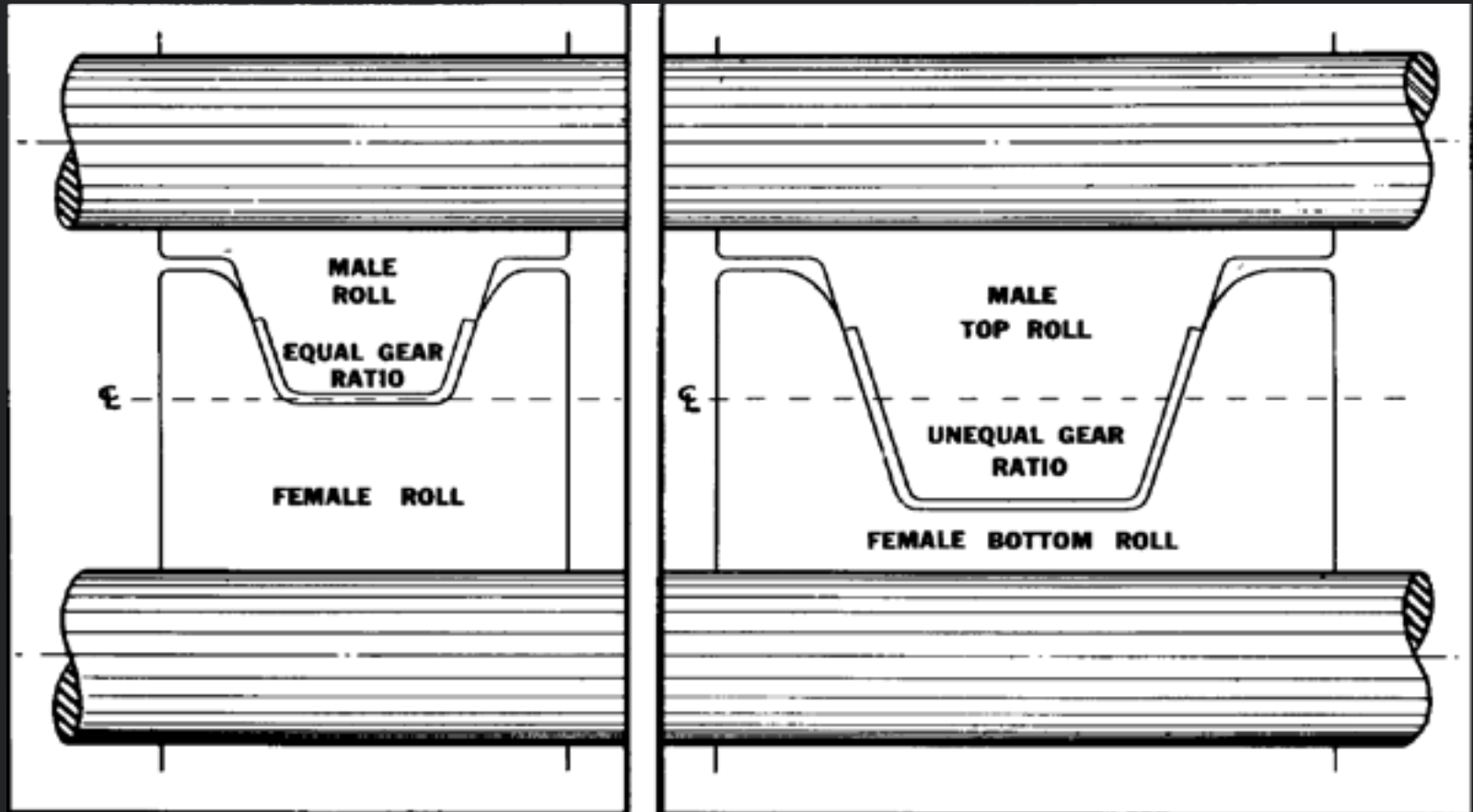

The roll “pitch” diameter is usually selected to engage a given profile at its widest and most nearly horizontal area. This area is important as it provides the most effective and balanced traction. The ratio between the pitch diameter of the top and bottom rolls must be the same as the ratio of the gearing connecting the top and bottom spindles. Some manufacturers provide machines that are able to accommodate either equal ratio or unequal ratio rolls. The diagram below is a cross section through a stage of equal pitch diameter rolls. The drawing on the right shows the same roll stage in a machine fitted out for unequal ratio rolls. The pitch diameter in the latter is well below the mid-point between spindles and as you see, gains enough space to allow forming a much deeper section with the same vertical centers.

In machines to which only equal ratio rolls can be applied, deep sections are formed by so called “floating the pitch line”. This is not a good procedure but can be applied in specific instances, particularly where light gauge and perhaps narrow shapes are concerned. In principle, it involves a different pitch diameter in successive roll passes which, as each bottom spindle is driven at the same RPM, can lead to “roll fight” between passes, excessive gear loads and excessive HP demands.