For coil-fed roll forming systems, there are two options when it comes to choosing a measuring system that can size your parts by activating the cutoff at the end of the line: open loop and closed loop. These two cutoff systems can both measure and cut accurate lengths of product, but one is much more efficient than the other. In this post, we'll discuss the difference between open loop and closed loop cutoffs in roll forming and why one may be more efficient for your operation than the other.

Open Loop vs. Closed Loop Cutoffs

An open loop cutoff is the more traditional method of timing the cutoffs on a roll forming system. In an open loop cutoff, a timed mechanical process is used to accelerate the die and make the cut in the material. However, this mechanical method is set up before the material is roll formed and cannot be simply adjusted without shutting down the entire coil line. There is no way to provide feedback to the open loop cutoff while the line is running, so this type of cutoff is unable to make high-speed adjustments based on any variations in the system. Additionally, this type of cutoff is extremely high maintenance to run.

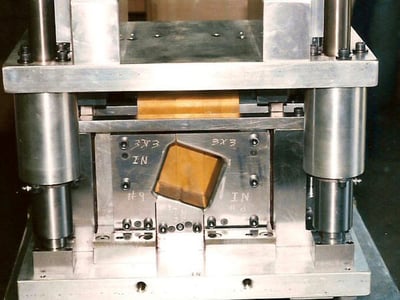

However, a closed loop cutoff system provides a range of benefits to your roll forming process that a traditional open loop system cannot. A closed loop cutoff is more productive than an open loop system because it produces more consistent, higher quality product with minimal monitoring and maintenance. Using its built-in positioning device, a closed loop cutoff positions the cutting die over the cut point while moving at the same speed as the material coming down the line.

However, a closed loop cutoff system provides a range of benefits to your roll forming process that a traditional open loop system cannot. A closed loop cutoff is more productive than an open loop system because it produces more consistent, higher quality product with minimal monitoring and maintenance. Using its built-in positioning device, a closed loop cutoff positions the cutting die over the cut point while moving at the same speed as the material coming down the line.

Because of its positioning feedback, a closed loop cutoff offers the ability to increase your line speed and scrap savings while reducing downtime, leading to increased profits for your operation. Part quality is also improved thanks to cleaner cuts as well as more accurate and consistent part measuring, and the life of the cutoff die is significantly extended. Minimal intervention with the machine is needed, especially while the press cycle is running, meaning that fewer operators will be at a safety risk thanks to the automated system. Considering all of the benefits of a closed loop cutoff, investing in machines or upgrades using this technology may be a valuable way to increase productivity in your roll forming operation.