If you are considering adding a straightener to your roll forming operation, there are a number of factors to consider before making your purchase. In this post, we'll explain when a straightener might be the right choice for your operation and how it compares to using a leveler.

Straighteners vs. Levelers in Roll Forming and Tube Mills

There are a few key differences that will help determine whether you need a straightener or a leveler for your operation.

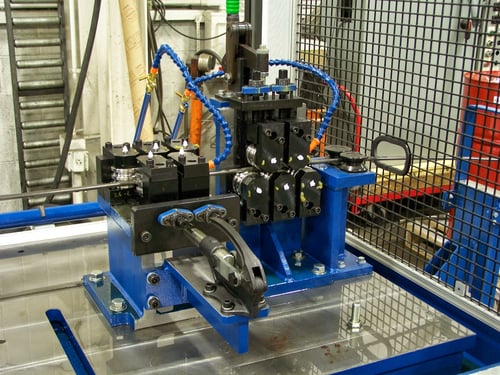

Most straighteners will have backup rolls. The work rolls are supported by the backups and they prevent deflection of the work roll.

Meanwhile, with a leveler, there could be multiple sets of backup rolls, and those backup rolls are intended to induce deflection of the work rolls. And that’s why a straightener will only handle and address coil set in a coil, versus a leveler’s ability to handle many different coil defamations.

Should You Add a Straightener to Your Roll Forming Line?

Primarily, if you are working with coil set in that material, you will want to have a straightener as a part of a line to remove coil set. A straightener is actually designed to remove the coil set before the material is introduced to a secondary piece of equipment or a loop. For material that’s not cold-rolled or mild steel (HSLA type materials), you definitely have to have a straightener. However, if you are working with coil conditions other than coil set, that's a situation where you would need a leveler rather than a straightener.

Based on the application, coil is going to come in a number of different formats. Some applications have to be completely flat in order for the efficiencies of the product to be as energy efficient as possible. In roll forming, we tend to straighten all the material throughout the coil because of the punching, which is similar to press stamping applications. The punching is very important, and we can’t have really coil set affecting where the hole locations are as we’re punching.