The use of light gauge steel drywall framing stud, track and accessories in construction is growing on a world wide basis. Though this is good news for the steel framing industry, it still remains a very competitive market for manufacturers of metal construction machinery. The demands of higher quality product requiring consistent finished materials which must comply with all recognized standards force manufacturers to have greater flexibility in an effort to remain relevant in the market. Producers must be able to provide materials on a “just-in-time basis” and avoid maintaining excess inventory. This requirement for higher productivity, while making the best use of fixed assets and labor is pushing the industry forward. The incorporation of a state-of-the-art accessory unit can move a company far ahead of the competition in quality, flexibility and productivity. This article will highlight the advantages to various accessory system types.

An integrated production line is custom designed system for all light steel framing accessories, including corner bead, furring channels, angles, CRCs, J-weeps and resilient channels. Compact accessory units are specifically engineered to maximize limited floor space and efficiently thread up coil quickly and easily. A single mandrel uncoiler is a key component to an efficient system. This type of design can handle up to six thousand pounds, while an optional double mandrel unit allows operation from one side while coil is loaded to the other. When it is time to switch sides, the reel is simply rotated, threaded up and the system is ready to operate with the second coil quickly in place.

An integrated production line is custom designed system for all light steel framing accessories, including corner bead, furring channels, angles, CRCs, J-weeps and resilient channels. Compact accessory units are specifically engineered to maximize limited floor space and efficiently thread up coil quickly and easily. A single mandrel uncoiler is a key component to an efficient system. This type of design can handle up to six thousand pounds, while an optional double mandrel unit allows operation from one side while coil is loaded to the other. When it is time to switch sides, the reel is simply rotated, threaded up and the system is ready to operate with the second coil quickly in place.

Equipment incorporating a powered straightener-feeder removes coil set and features a speed matching algorithm that works with the roll former. A rugged five roll straightener-feeder can easily handle steel dimensions up to 6 inches wide and 16 gauge material thickness. Machinery that exhibits a micrometer adjustable edge guide ensures proper alignment with the roll former to make thread-up quick and easy when switching between profiles. In addition, hardened upper rolls are individually adjustable to provide the exact roll pressure needed while keeping the rolls parallel. The following station then punches holes and shears the strip to the precise length prior to the roll former.

Machinery that exhibits a micrometer adjustable edge guide ensures proper alignment with the roll former to make thread-up quick and easy when switching between profiles. In addition, hardened upper rolls are individually adjustable to provide the exact roll pressure needed while keeping the rolls parallel. The following station then punches holes and shears the strip to the precise length prior to the roll former.

Continuous pattern rotary punches are available as options to accessory systems and provide unmatched production speed and compact design compared to traditional perforating methods. With no press or discrete feeding equipment, the operation and maintenance is considerably simplified when manufacturing corner beads or forming holes in metal drywall studs. With the “no hole punching” option, the rotary can simply roll off line for storage or later use.

In addition, a sophisticated rotary shear can provide high performance in a compact system and maintain tight tolerances at high speeds. Incorporating an economical pre-cut method can eliminate the high cost of various cut-off dies for different profiles along with minimizing lost production time that comes with constantly changing out cut-off tools. In addition, one shear blade can have the capacity to cut 25 to 16 gauge material up to 6 inches wide.

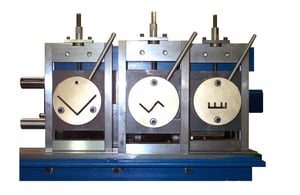

Certain roll formers serve as multi-profile accessory machines, providing remarkable flexibility, productivity and ease of use in roll forming steel framing accessories. The roll former is capable of complete change over, from one unique profile to another, in less than 1 minute. A simple hand-crank apparatus queues the digital readout to traverse the machine in the desired position of the next profile.

This type of accessory system’s permanent tooling can produce any of the necessary profiles by simply traversing the roll former to the desired product specification. The operator simply threads up the material, keys in the part length, quantity and selected line speed. There are no manual adjustment screws to set on the roll former, punch or shear. Thus nearly eliminating the potential of human error.

There are significant opportunities to increase profits with an advanced accessory system, versus a conventional mill system. These increased profits are largely based on the system changeover time from one product to another.