In this series on our blog, we'll go through each press type one by one and discuss their features, advantages, and disadvantages and how all those elements make them the right choice for certain applications. In this post, we'll focus on the advantages of hydraulic presses in particular roll forming applications and operations.

Hydraulic Presses - Part 3

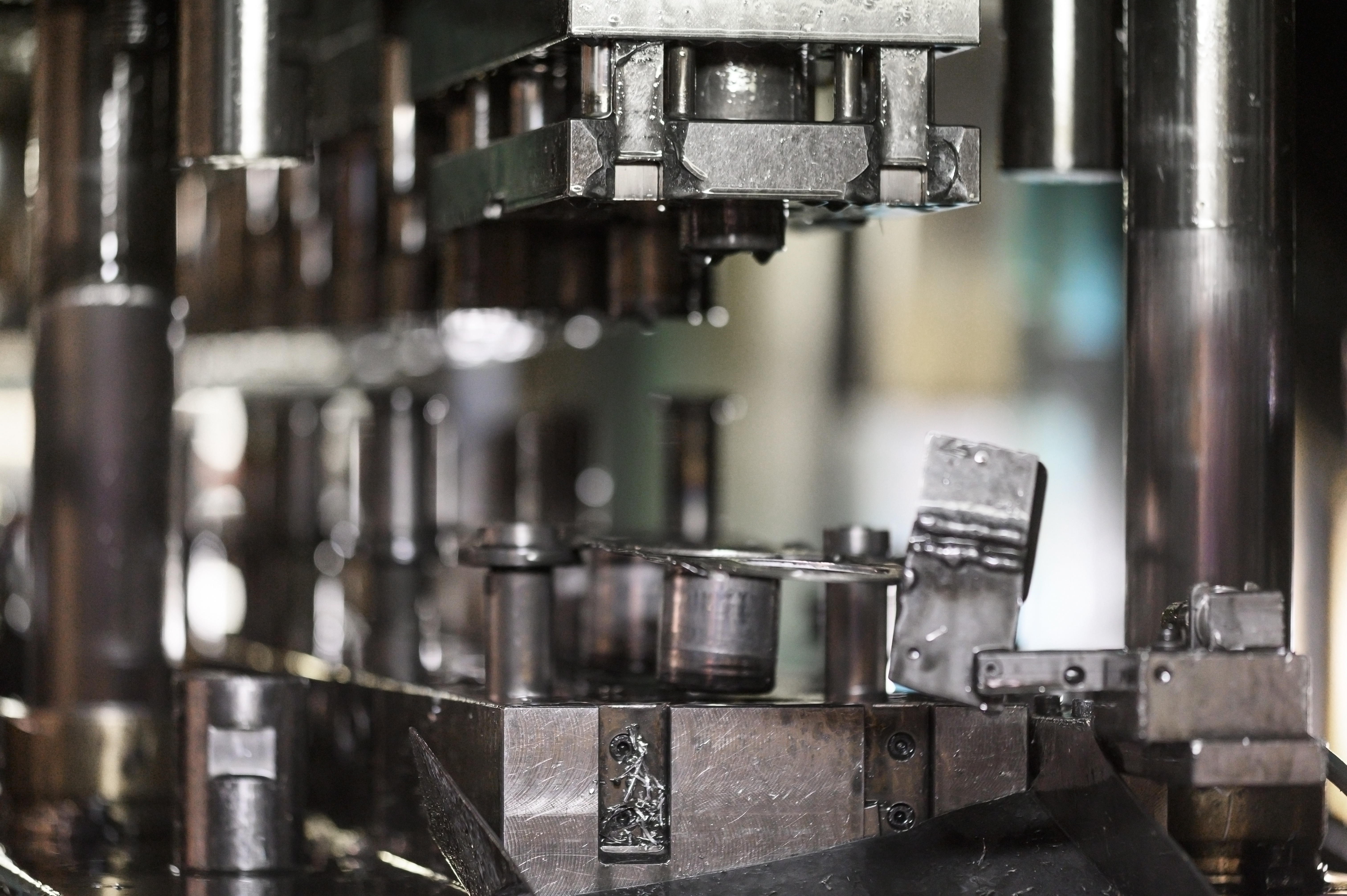

Hydraulic presses are a critical component of modern roll forming systems, offering unparalleled precision and adaptability. Their unique characteristics make them an ideal choice for manufacturers seeking efficiency and quality in forming and cutting operations. In this post, we’ll explore the key advantages of hydraulic presses in roll forming, focusing on their precision, versatility, and ability to handle demanding materials and designs.

Hydraulic presses are a critical component of modern roll forming systems, offering unparalleled precision and adaptability. Their unique characteristics make them an ideal choice for manufacturers seeking efficiency and quality in forming and cutting operations. In this post, we’ll explore the key advantages of hydraulic presses in roll forming, focusing on their precision, versatility, and ability to handle demanding materials and designs.

Benefits of Using Hydraulic Presses in Roll Forming Operations

Precision and Accuracy

One of the most significant advantages of hydraulic presses is their ability to apply constant and controlled force throughout the pressing action. This precision ensures:

- Tight Tolerances: Components are consistently produced to exact specifications, even with complex geometries.

- Smooth Finishes: Material deformation is controlled, reducing imperfections and enhancing the quality of the finished product.

Hydraulic presses are particularly well-suited for roll forming applications requiring exact measurements and high-quality finishes.

Versatility in Material Handling

Hydraulic presses excel in working with a wide variety of materials, including high-tensile strength metals often used in roll forming operations. Their ability to manage these materials ensures:

- Consistent Performance: The press maintains accuracy and effectiveness across different material types.

- Application Flexibility: Suitable for applications ranging from light-duty tasks to heavy-duty industrial requirements.

This versatility allows manufacturers to produce a broad range of products with the same hydraulic press, making it a cost-effective and adaptable solution.

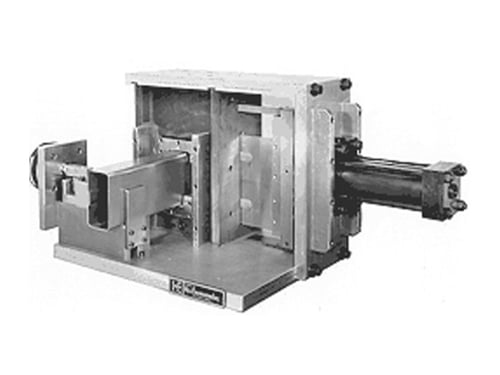

Support for Complex Designs

Another key advantage of hydraulic presses is their ability to accommodate various die designs. This adaptability enables seamless integration into roll forming operations, providing benefits such as:

- Customizable Features: Hydraulic presses can work with dies tailored to specific production needs, allowing for intricate shapes and patterns.

- Enhanced Compatibility: These presses integrate easily into existing roll forming systems, supporting diverse operations like piercing, notching, embossing, and cut-off tasks.

By supporting complex die designs, hydraulic presses ensure manufacturers can meet unique design requirements without compromising efficiency or precision.

Reliable Performance Under Challenging Conditions

Hydraulic presses are engineered to handle demanding conditions, including challenging geometries and high-tensile materials. Their robust construction and advanced control systems ensure they can consistently deliver:

- Durability: Hydraulic presses are built to withstand rigorous use, making them a long-lasting investment.

- Operational Consistency: Even under high pressure, they maintain reliable performance, ensuring uninterrupted production.

These qualities make hydraulic presses indispensable for roll forming systems that require precision and strength in every operation.

Hydraulic presses bring a host of advantages to roll forming systems, including precision, versatility, and the ability to handle complex designs and high-tensile materials. Their ability to deliver consistent and reliable performance ensures manufacturers can meet demanding production standards while maintaining efficiency and quality.