In roll forming systems, presses play a critical role in shaping and cutting materials to precise specifications. There are three major types of presses that roll forming professionals should know about: mechanical, air, and hydraulic presses. Each type of press has its unique advantages and disadvantages, and selecting the right one requires careful consideration of your specific application needs and constraints.

By understanding the differences between them, you can make more informed equipment decisions that enhance your roll forming system's operations and design. Each type of press has unique advantages and disadvantages, and selecting the right one requires careful consideration of your application's specific needs and constraints.

In this series on our blog, we'll go through each press type one by one and discuss their features, advantages, and disadvantages and how all those elements make them the right choice for certain applications. In this post, we'll focus on hydraulic presses, their components, and their operational processes.

Hydraulic Presses - Part 2

Hydraulic Press Key Components

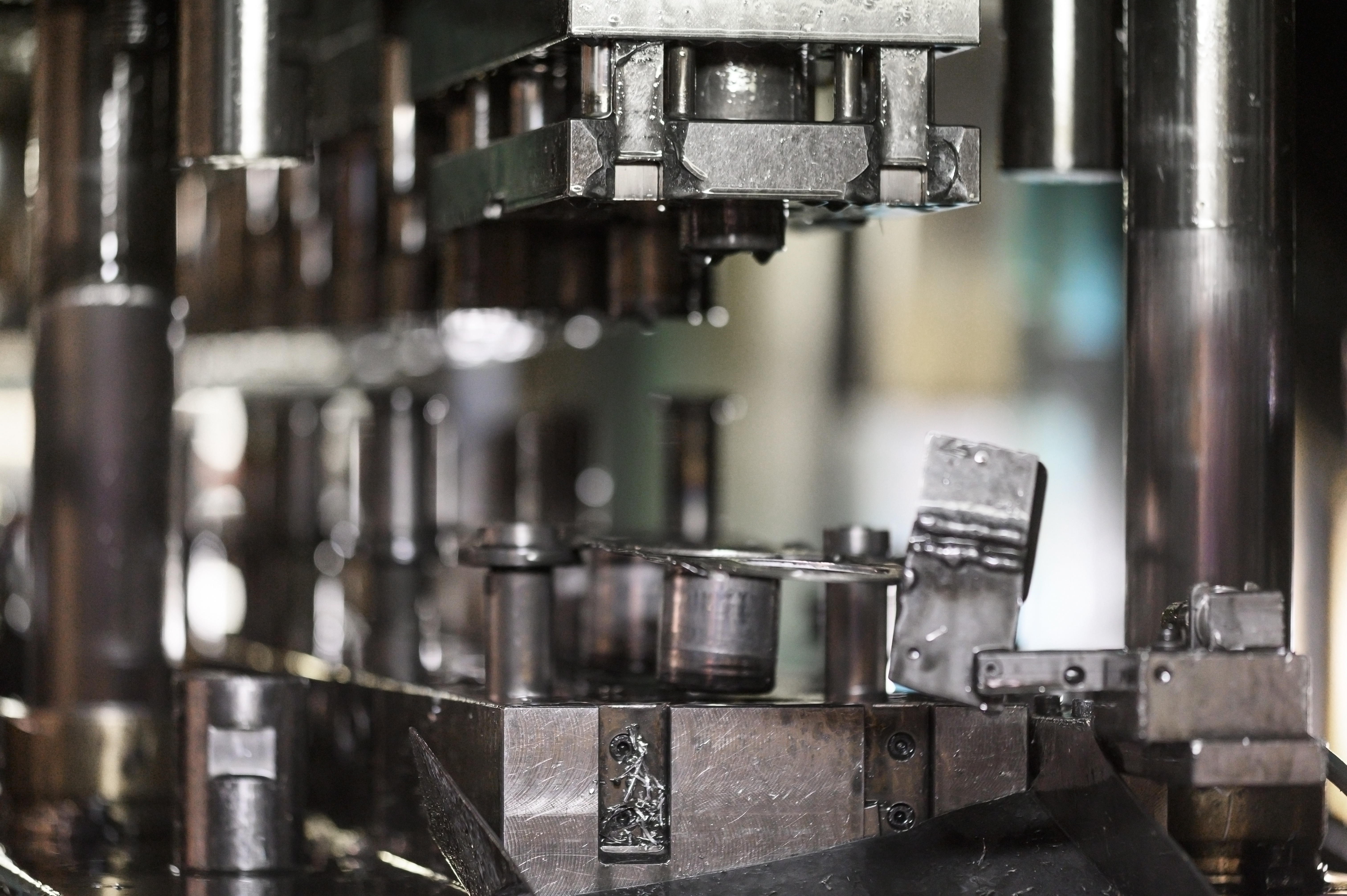

Hydraulic press owners and operators should be familiar with these key components of a standard hydraulic system.

- Hydraulic Cylinder: The core component of the press, the cylinder moves the ram or slide up and down. It is powered by pressurized hydraulic fluid (usually oil).

- Hydraulic Power Unit: This unit includes a motor, pump, and fluid reservoir, which work together to supply pressurized fluid to the cylinder.

- Control System: Modern hydraulic presses often feature programmable controls (PLC) that manage the force, stroke length, speed, and cycle timing. These controls provide high levels of accuracy and repeatability.

- Die Set: Mounted to the ram and bed, the die performs the specific operation (cutting, punching, forming, etc.) on the moving or stationary metal strip as it passes through the roll forming system.

Hydraulic Press Operation Processes

Hydraulic presses offer repeatable accuracy, controlled force, and adaptable operation, making them ideal for roll forming systems and a wide range of industrial applications. Proper understanding of their operation ensures efficient output, minimized downtime, and extended machine life.

- Material Advancement: The metal strip is fed through the roll forming system, typically moving continuously or in synchronized stages.

- Press Activation: As the material reaches a designated point, a sensor or controller triggers the hydraulic press.

- Controlled Force Application: The hydraulic system moves the ram and die downward with precise force to perform the desired operation (e.g., punching a hole or shearing the part).

- Retraction: Once the stroke is completed, the ram retracts, and the material continues moving through the line.

- Repeat Cycle: This cycle repeats in rhythm with the roll forming process, synchronized by open loop or closed loop measuring systems, or pick-up fingers to ensure precise timing and positioning.

Why Use Hydraulic Presses in Roll Forming?

- Consistent Force Application: Unlike mechanical presses, hydraulic presses apply constant pressure throughout the stroke, which is especially helpful for deep or complex forms.

- Precision and Control: Programmable settings allow for exact adjustment of speed, pressure, and stroke depth.

- Versatility: They can be used for a variety of operations with interchangeable dies.

- Safety and Quiet Operation: Quieter and smoother than air presses, with advanced safety features such as pressure relief valves and emergency stops.

Hydraulic presses in roll forming systems provide accurate, consistent, and customizable force to perform essential forming and cutting operations. Whether integrated as a self-contained unit or as part of a flying press setup, their adaptability and precision make them a key asset in modern roll forming lines.