With the rapid advancement of manufacturing technology, the selection of presses and measuring systems for roll forming has become more varied and complex than ever. There are three major types of presses that roll forming professionals should know about: mechanical, air, and hydraulic presses.

By understanding the differences between them, you can make more informed equipment decisions that enhance your roll forming system's operations and design. Each type of press has unique advantages and disadvantages, and selecting the right one requires careful consideration of your application's specific needs and constraints.

In this series on our blog, we'll go through each press type one by one and discuss their features, advantages, and disadvantages and how all those elements make them the right choice for certain applications.

Air Presses - Part 2

Air Press Key Components

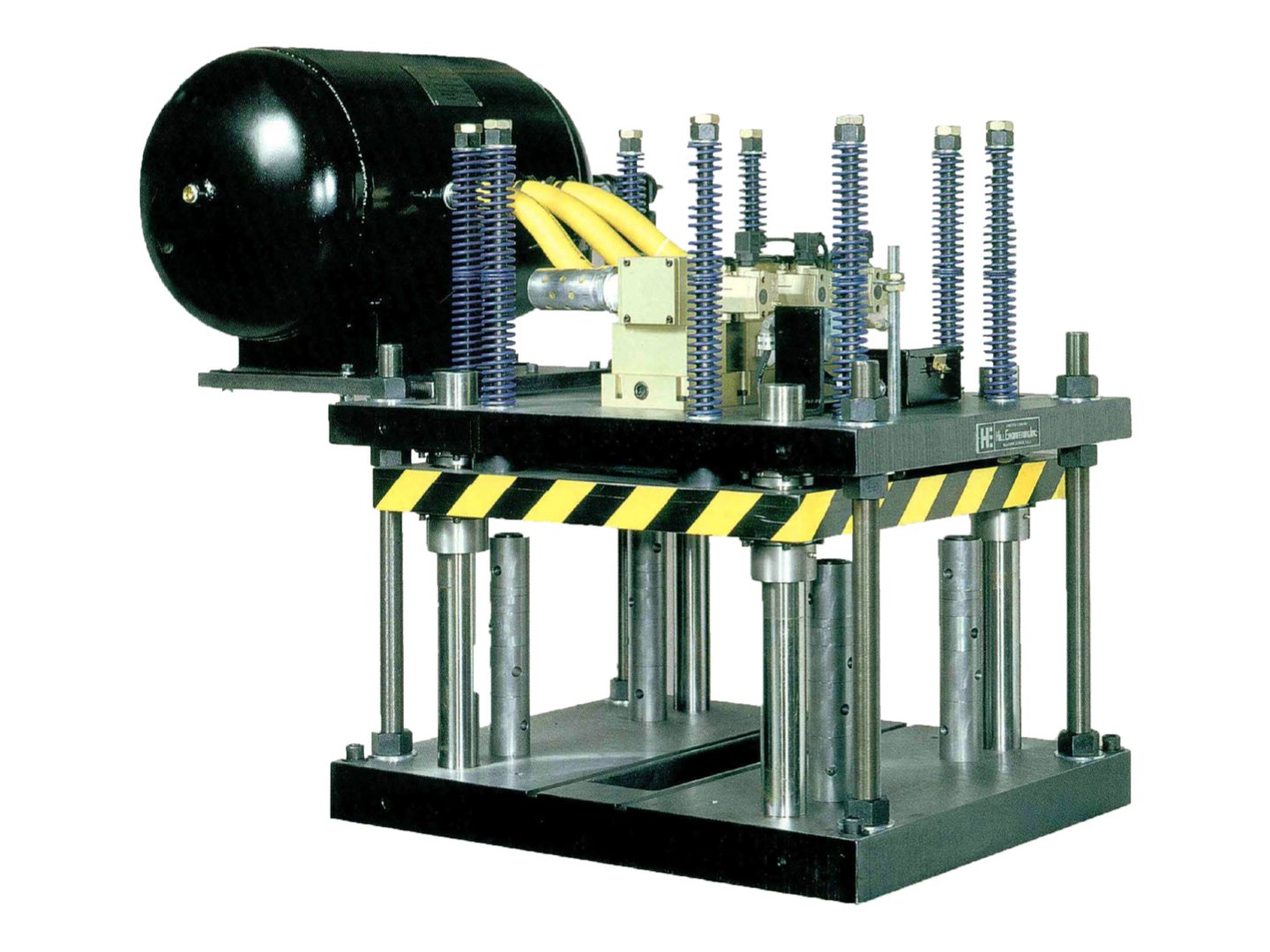

The key components of an air press include:

- Air Compressor: Provides the compressed air necessary to generate force.

- Control Valve: Regulates the flow and pressure of the air entering the press.

- Cylinder: Converts the compressed air into mechanical motion.

- Ram: The moving part that delivers force to the workpiece.

- Frame: A sturdy structure that supports all components and absorbs the force generated during operation.

Air Press Operation Processes

The operation of an air press in a roll forming system typically follows these key steps:

- Air Compression: Compressed air is supplied from an external air compressor and stored in a reservoir.

- Control Activation: The operator or automated control system triggers the press cycle, opening a control valve to direct air into the cylinder.

- Piston Movement: The pressurized air pushes the piston inside the cylinder, generating linear motion.

- Force Application: The piston drives the ram downward, delivering force to the tooling to perform tasks like punching, notching, or shearing.

- Return Stroke: After the operation, the control valve redirects the airflow or vents it, allowing the piston and ram to return to their starting position.

- Cycle Repeat: The system resets and is ready for the next press cycle, enabling high-speed, repeatable operations.

This process allows for fast, controlled, and efficient integration into continuous roll forming lines, especially for lighter-duty applications.