Roll design encompasses the configuration of roll tooling and machinery on a rollforming line. In order to understand how your coil lines and other roll forming machinery creates the cross section you need to produce, a basic understanding of roll design and tooling is necessary. In this post, we'll discuss roll materials you'll commonly use in roll forming and explain split rolls and combination tooling on the line.

Roll Materials and Roll Life

Rolls are usually made from tool steel, the grade being dependent on the expected production and finish of the piece part. For general duty applications where a smooth finish strip is to be formed or when shapes are formed from hot rolled, unpickled, steel, a High Chrome- High Carbon tool steel (AISI D-2) with about 1.5% carbon and 12% chrome is to be suggested. This generally heat treats to 60-63 Rockwell “C” and represents about 2 to 2½ times the life of the previously used oil hardening tool steel. This tool steel has good wear quality and for the average run of light gauge cold formed sections could be expected to roll several, on the order of 3 to 5 million feet or more before regrinding. Generally speaking, 4 to 5 regrinds can be made before the rolls are scrapped.

For specific industry and product applications, other materials may be used. For light gauge, pre-painted or galvanized wide products, such as building panels or metal roofing, chromed coated alloy steel may be used, due to the liberal tolerances of the application and the light forming duties involved. Additionally, if there is a nonmagnetic or temperature sensitive environment for the roll tooling, such as inline welding or heat treating, other materials may be required, specifically aluminum bronze (non-magnetic) or AISI H13 tool steel (heat resistance compared to D2).

Finally, for extremely high speed, high wear applications, most commonly tube mills, tungsten carbide tooling may be used. Carbide tooling may offer an order of magnitude improvement in tooling wear, but it is substantially more brittle than toolset, so care must be taken in the handling of the tooling pieces.

Split Rolls and Combination Tooling

Rolls are split where necessary to facilitate machining, grinding or for size changes, and also to provide for easy replacement of a roll piece that might be subject to extreme wear. In general, no roll pieces exceed 6” wide, meaning that wide shape rolls are made up in sections, sometimes even of different materials, according to the service requirement. Such would be the case for a wide panel in which flats predominate, the flat roll pieces being a soft machine steel, the forming or working portions of tool steel.

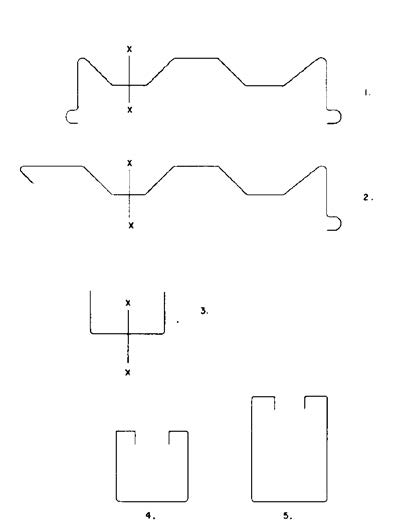

Closely related to the subject of splitting rolls is the use of combination tooling, to enable a manufacturer to produce several shapes with a minimum of tooling outlay. Note the similarity of sections #1 and #2 on the figure above. Combination tooling was provided for these. The basic set being that to the right of line XX with separate roll sets for the portions to the left of this line. Looking at Section #3, splitting a set of channel rolls along line XX as shown, allows the forming of numerous widths simply by adding spacers at the split. The shapes shown as #4 and #5 employ another type of combination roll arrangement involving split rolls with spacers for width in the first passes, a common set of bottom rolls, and two (2) sets of top rolls in the subsequent passes.