In today's fast-paced manufacturing landscape, optimizing production processes is crucial for businesses to maintain a competitive edge. One significant factor that affects efficiency is the lead time associated with ordering metal forming and fabricating machinery. Understanding the lead times involved in acquiring these essential machines is vital for effective production planning and resource allocation. In this blog post, we will delve into modern industry lead times for metal forming and fabricating machinery, exploring the factors influencing them and offering insights to streamline your production operations while acquiring these machines.

The Significance of Metal Forming Machinery Lead Times

Lead times play a pivotal role in manufacturing operations as they impact your overall production schedule. Knowing how long it takes to acquire new machinery helps businesses manage inventory, plan production cycles, and meet customer demand effectively. Shorter lead times can lead to increased productivity and improved customer satisfaction, while longer lead times may result in production delays, missed deadlines, and potential revenue losses.

Factors Influencing Machinery Lead Times

Several factors contribute to the lead times associated with metal forming and fabricating machinery. Understanding these variables enables manufacturers to make informed decisions and set realistic expectations. Here are some key lead time-related factors to consider when making machinery and equipment purchases for your business.

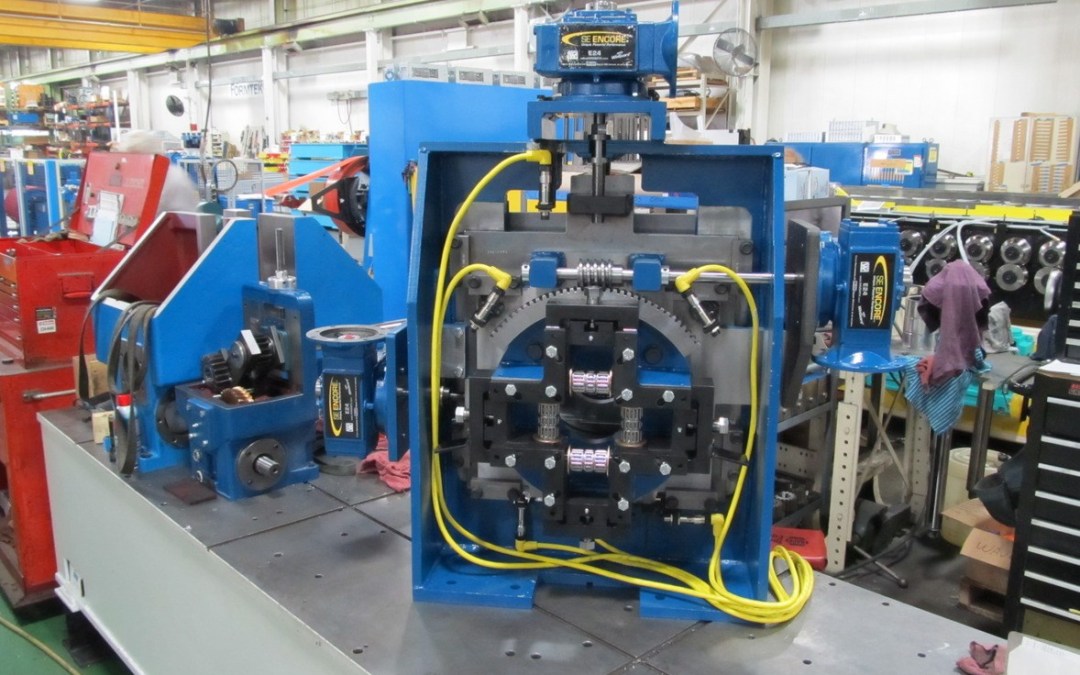

- Machine Type and Complexity: Lead times can vary based on the type and complexity of the machinery being ordered. Customized or specialized machines often require more time for design, engineering, and manufacturing.

- Manufacturing Capacity: The capacity of the machinery manufacturer plays a crucial role in determining lead times. Manufacturers with high demand or limited production capabilities may have longer lead times compared to those with more efficient production processes.

- Supply Chain and Raw Materials: Availability of raw materials and components can significantly impact lead times. Delays in the supply chain, shortages, or unexpected disruptions can lead to extended waiting periods.

- Order Volume and Customization: Large orders or customized machinery may require additional lead time due to increased complexity and the need for specialized production processes.

Strategies to Minimize Your Machinery Order Lead Time

Reducing lead times for metal forming and fabricating machinery can enhance operational efficiency and ensure timely production. Here are some strategies to consider to help expedite your next machinery order.

- Partnering with Reliable Suppliers: Choosing reputable suppliers known for their prompt deliveries and high-quality machinery can help minimize lead times.

- Effective Communication and Planning: Open and transparent communication with machinery manufacturers can help align expectations and ensure smooth workflow throughout the ordering process.

- Streamlined Manufacturing Processes: Working with suppliers or manufacturers committed to continuous improvement efforts, such as lean manufacturing principles, can enhance efficiency and reduce lead times.

- Early Order Placement: By placing orders well in advance while considering future production requirements, businesses can avoid unnecessary delays.

Industry lead times for metal forming and fabricating machinery are critical considerations for manufacturers seeking to optimize their production processes. Understanding the factors that influence lead times and implementing strategies to minimize them can significantly impact operational efficiency, customer satisfaction, and overall business success. By staying informed, fostering strong supplier relationships, and implementing efficient planning, manufacturers can navigate lead times effectively and achieve streamlined production operations.